MATERIAL ENGINEERING

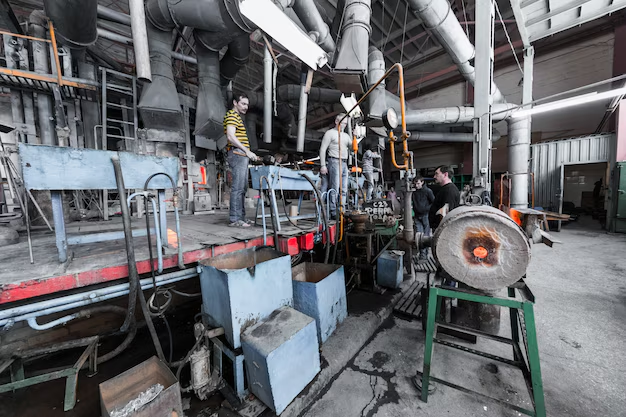

Materials Engineering specialized equipment is required for testing, processing, and manufacturing materials used in various industries, including energy, aerospace, automotive, and construction. Materials engineers use this equipment to analyze the properties of materials, optimize manufacturing processes, and ensure the quality of the products.

Here’s an overview of some common Materials Engineering equipment that might be relevant to your import/export business if you’re dealing with products for industries that require advanced materials:

SERVICE DETAILS

At UniGlobal Impex , we specialize in the import and export of cutting-edge material engineering equipment designed to meet the needs of industries worldwide. With a focus on providing high-quality products, we connect our clients with state-of-the-art equipment for testing, processing, and analyzing materials across diverse industries such as automotive, aerospace, energy, construction, and manufacturing.

Whether you’re a manufacturer, research institution, or engineering firm, we have the right tools to help you enhance your production processes, ensure quality, and innovate in your field.

- We supply a broad range of advanced material engineering equipment used for testing, processing, and analyzing materials. From tensile testing machines and hardness testers to furnaces, CNC machines, and coating systems, we provide everything your operations need to succeed.

- Our equipment is sourced from leading global manufacturers, ensuring top-notch performance, durability, and precision.

- Tensile Testers: Measure the strength and elongation of materials to ensure they meet the necessary specifications.

- Hardness Testers: For determining the hardness of metals, polymers, and composites, ensuring their suitability for high-performance applications.

- Impact Testing Machines: Test a material’s ability to withstand sudden forces and stresses, providing essential data for safety and durability.

- Fatigue Testing Equipment: Measure material resilience under cyclic loading to predict performance under repetitive stresses.

- Scanning Electron Microscopes (SEM): Analyze the microstructure of materials with high resolution, allowing for defect detection and quality assurance.

- X-Ray Diffraction (XRD): Assess the crystallographic structure of materials, helping you optimize material selection and performance.

- Fourier Transform Infrared Spectroscopy (FTIR): Identify chemical compositions and analyze polymer characteristics to ensure quality in product manufacturing.

PROJECT MISSION

At UniGlobal Impex, our mission is to empower industries worldwide by providing high-quality, reliable, and innovative material engineering equipment. We are committed to helping businesses in diverse sectors—such as manufacturing, aerospace, energy, and research—optimize their material testing, processing, and production capabilities.

Through our comprehensive selection of advanced equipment, expert consultation, and exceptional customer service, we aim to support our clients in achieving their operational goals, improving efficiency, and advancing technological innovation.

Delivering Quality and Precision

Empowering Innovation in Material Science

Ensuring Reliability and Durability

Supporting Sustainable Practices

Building Long-Term Partnerships

Global Reach with Local Expertise